Technology

Advanced materials, cutting-edge technology, and extensive engineering expertise drive innovative design breakthroughs that establish new industry standards. With in-house design, R&D, and manufacturing, we leverage the latest tech to deliver unparalleled high-end quality.

LOTUS GRILLE

Inspired by the Lotus flower, this design is engineered to provide an acoustically transparent solution that protects the loudspeakers while enhancing the aesthetic appeal. The unique pattern reduces the "horn" effect commonly seen in traditional grilles.

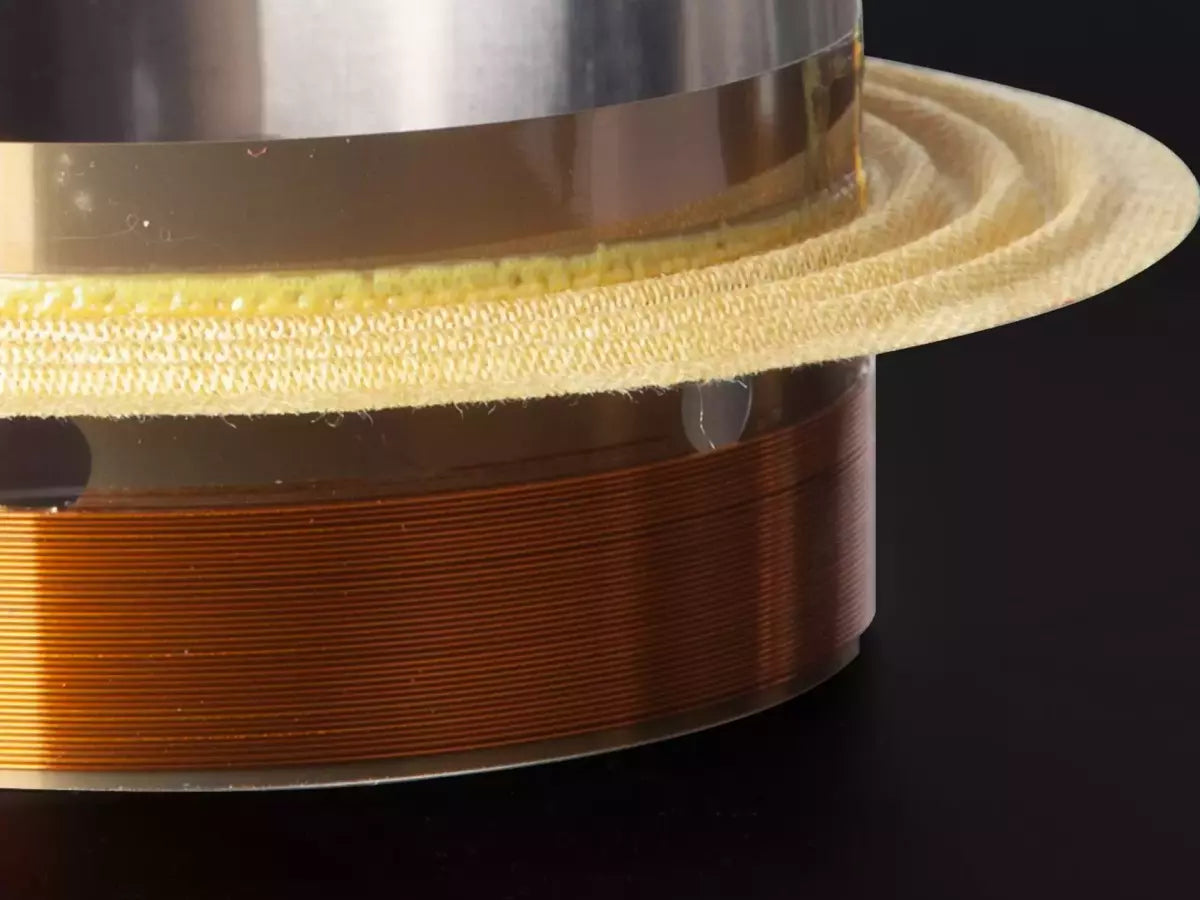

MOREL EVC™

EXTERNAL VOICE COIL

Relocating the speaker voice to sit externally allows for it to be up to three times larger than those found in standard loudspeakers, resulting in better heat dissipation, enhanced power handling, and improved linearity.

The EVC™ design positions the magnetic motor system within the voice coil, eliminating stray magnetic flux and ensuring all magnetic energy is efficiently directed to the voice coil. This innovative architecture is over 90% more efficient than traditional designs, magnetically shielded, and exceptionally compact.

HEXATECH™ ALUMINIUM VOICE COIL

Crafted from 100% aluminum wire arranged in a honeycomb pattern, the Hexatech™ voice coil reduces air gaps in the coil windings, boosting thermal efficiency by up to 20%.

INTEGRA DESIGN

The Integra, Morel's point-source system, represents a groundbreaking advancement in speaker design. Its point-source topology addresses the acoustic challenges commonly found in traditional coaxial systems. By positioning the tweeter and woofer along the same axis as a single sound source, it ensures seamless integration, delivering omni-directional time alignment, improved imaging, and enhanced sound dispersion.

TWEETER TECHNOLOGIES

ACUFLEX™ COATING

The Morel Acuflex tweeter coating is a proprietary damping compound carefully applied to tweeter domes to enhance detail and smoothness by effectively reducing distortion, resonances, and unwanted high-frequency artifacts.

IMPROVED DISPERSION WAVEGUIDE

Engineered to improve sound dispersion while minimizing diffraction and phase errors, the IDW enhances coherency, transparency, and detail in the high-frequency range.

TALL DOME GEOMETRY

The consistent dome radius increases dome height to improve power handling, control breakup modes, and enhance off-axis dispersion. The result is greater clarity and a smoother, more natural high-frequency response across a wider listening area.

CONE MATERIALS

Morel employ a number of different cone structures throughout their various ranges. The materials shown here are:

- Carbon Fibre/Rohacell Sandwich

- Damped Polymer Cone (DPC)

- Composite Cellular Fibre

- Composite Paper

The material selection for each woofer range is dependent on the driver geometry, motor system, intended power and budget, with the common theme across all materials being low weight and high rigidity.

CAR FILTER

Controlled Acoustic Resistance enhances acoustic loading by regulating airflow within the driver, simulating the effects of a cabinet while boosting power handling by 30%. This results in better control over cone movement, delivering improved bass dynamics.